Overview

The electric vehicle (EV) revolution is underway. In 2022 over 10 million EVs were sold and sales are projected to surge to yet another record in 2023. No longer is the internal combustion engine the only form of technology on the road; EVs share of the car market has skyrocketed from 4% in 2020 and is predicted to reach 18% in 2023. This explosive growth in electrified transportation will forever change the status quo for the car manufacturing industry and for the global energy economy.

The electric vehicle (EV) revolution is underway. In 2022 over 10 million EVs were sold and sales are projected to surge to yet another record in 2023. No longer is the internal combustion engine the only form of technology on the road; EVs share of the car market has skyrocketed from 4% in 2020 and is predicted to reach 18% in 2023. This explosive growth in electrified transportation will forever change the status quo for the car manufacturing industry and for the global energy economy.

The historic shift to powering cars with domestically-produced electricity is a big win for air quality, public health, energy security, and the environment. By 2030, the International Energy Agency predicts that EVs will avoid the need for at least 5 million barrels of oil a day. The transition to electrified transportation will, however, significantly increase demand for elements required for battery manufacturing. After decades of extracting and burning fossil fuels, the electrification of vehicles allows us to rethink how we power transportation and move forward in a way that minimizes harmful impacts on the environment and communities.

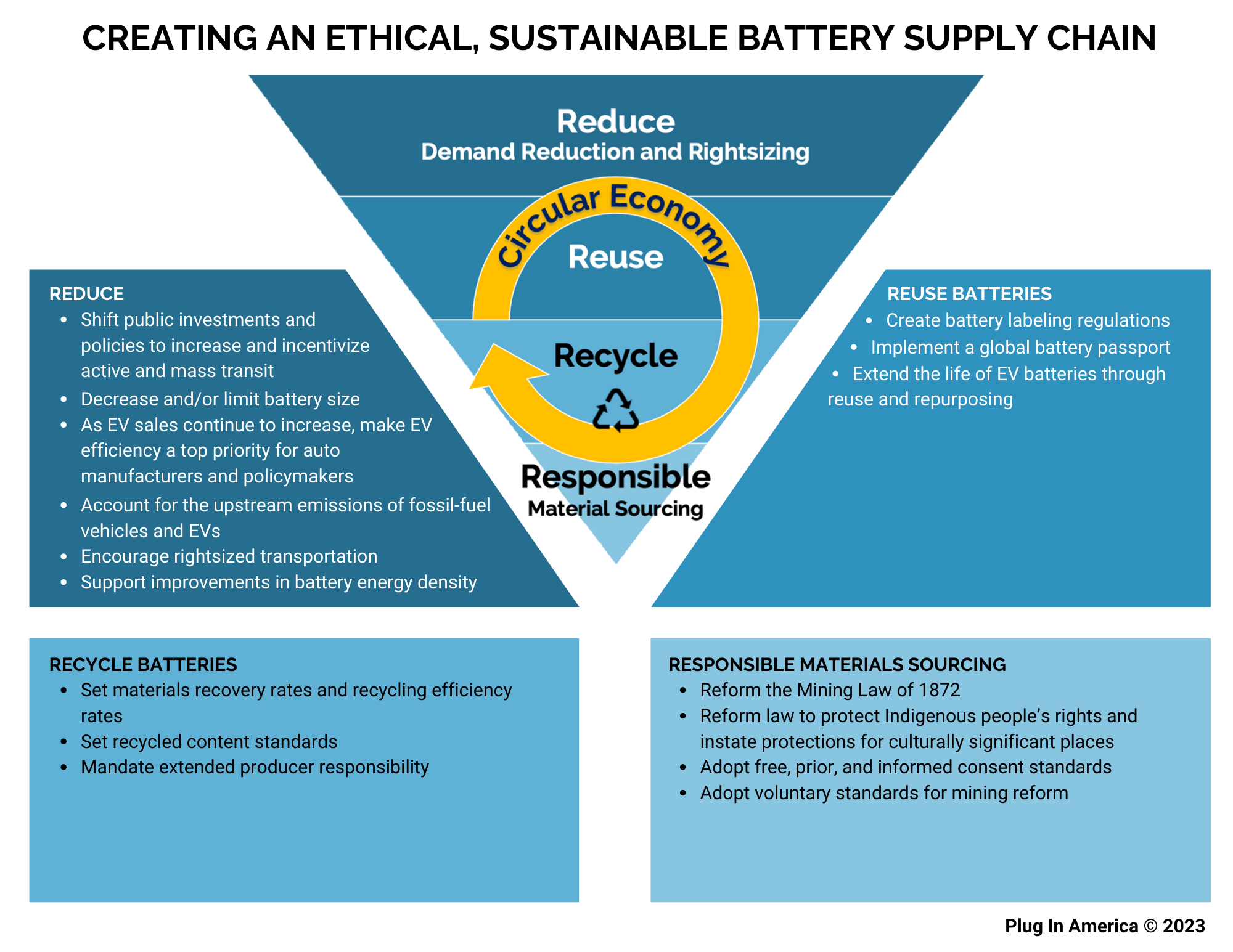

By prioritizing demand reduction, a circular economy, and responsible, ethical materials sourcing, we can decrease the need for new mining, cut localized vehicle pollution, advance transportation equity, and accelerate the decarbonization of the transportation sector. Plug In America’s position on procuring minerals for EV batteries follows four steps: reduce demand, reuse batteries, recycle batteries, and responsibly source materials.

Reduce

The first step in our solution set centers on reducing demand for battery minerals. To combat the climate crisis and optimize the efficiency of the minerals we extract, we must electrify vehicles while developing a just and accessible transportation system where more people can meet their everyday needs without a car. Options such as public transportation, car-sharing, and micro-mobility offer less resource-intensive transportation solutions for many lifestyles. Simultaneously, decreasing the size of EV batteries through technological innovation, such as increased EV efficiency and improving the energy density of batteries, while shifting to smaller vehicles will reduce the volume of minerals necessary to support the EV transition.

Reuse

Unlike gasoline vehicles which rely on the continuous extraction and burning of fossil fuels, many of the resources used to manufacture and power an EV can be reused and recycled. The circular economy elements of our solution set prioritizes keeping batteries in use and out of landfills through battery labeling, which offers instruction of where/how to dispose of a battery, and through the implementation of a digital battery identifier like a Global Battery Passport. Mechanisms like a Battery Passport can provide data about a battery’s individual environmental-social-governance (ESG) and lifecycle information including manufacturing history, provenance, materials used, recycled content, and more. High-quality data will help to inform decision-making and transparency at all stages of the battery value chain.

After powering a vehicle for 8-12 years, EV batteries typically retain almost 80% of their original capacity. Retired EV batteries are an excellent fit for second-life applications such as renewable energy storage, grid resilience, and backup power for homes and businesses. They can either be directly reused, or repurposed. Several exciting second-life applications include portable generators for emergency hospitals, solar streetlights, lower-power vehicles like golf carts or forklifts, and backup power for business and office buildings. As the EV market share continues to grow, an affordable and plentiful supply of retired EV batteries will serve as energy storage to support the electric grid, homes, and businesses.

Recycle

The minerals in an EV battery can be recycled almost infinitely. Research shows that while mining alone could meet the coming demand for EV battery minerals, recycling can support a significant portion of the minerals necessary for the growing EV market. According to Redwood Materials CEO J.B. Straubel, the metals in batteries don’t change or degrade, so the materials from old batteries can be made into new batteries without any tradeoffs in performance or battery life. Dunn et al. found “In 2050, recovered material can supply approximately 45–52% of cobalt, 40–46% of nickel, and 22–27% of lithium demand for EVs.” Building out domestic recycling can also mitigate supply and price volatility across global markets. Plug In America proposes setting comprehensive and material-specific recovery rate targets and recycled content standards to mandate materials recovery through the recycling and recirculation of recycled materials into new batteries. Additionally, we propose implementing extended producer responsibility. This shifts the burden for end-of-lifeproduct management from consumers to producers and helps ensure that end-of-life considerations are included in the design process.

Responsible Material Sourcing

Mining practices have a long history of social and environmental injustice. As of now, there is no such thing as “sustainable mining,” but there are emerging practices intended to mitigate negative impacts of mining to people and the planet. The transition to electrified transportation offers a timely catalyst to rethink our antiquated mining laws, which have not been changed in the US since 1872. Important principles for mining reform include robust environmental protections, prioritization of other land uses over mining, and intentional engagement and consultation with impacted communities.

We can balance the need for mineral extraction for the clean energy transition and ensure that Indigenous Peoples’ rights are upheld. Free, Prior, and Informed consent (FPIC) is critical to guaranteeing that Indigenous People are central to the decision-making processes for projects that may impact them. We recommend legislative pathways like ratifying and operationalizing the UN Declaration on the Rights of Indigenous Peoples which would impose legal requirements for companies to respect FPIC and provide avenues for consequences if they do not. In the absence of stringent regulations around mining. Plug In America recommends using The Initiative for Responsible Mining Assurance’s (IRMA) standards as a transparency tool to hold mining companies accountable for human rights, and environmental and labor conditions at mine sites.

Electric vehicles are a key component of creating a more sustainable and equitable transportation future. Plug In America supports reducing demand, reusing batteries, recycling used batteries, and responsible mineral sourcing to minimize the environmental and social impacts of transportation electrification.

US Federal Policy Recommendations

- Set overall and material-specific recovery rate targets and recycled content standards to mandate materials recovery through recycling and recirculation of recycled materials into new batteries.

- Implement battery labeling and a battery passport to support battery recycling. Battery passports can provide a wealth of information to inform better policy-making for governments, develop performance goals, and keep extracted materials in-cycle. Additionally, circular supply chain frameworks using data from battery passports can help make reusing and recycling used EV batteries self-sustaining and profitable for battery manufacturers.

- Mandate Extended Producer Responsibility. Placing responsibility for end-of-life product management on producers instead of the general consumer can catalyze safer, more efficient, and sustainable product design. Extended producer responsibility helps encourage markets to emerge that reflect the actual environmental impacts of a product.

- Establish and adopt mandatory requirements for mining best practices through administrative and legislative reform such as The Clean Energy Minerals Reform Act.

- Reform law to protect Indigenous people’s rights through new mining regulations that feature education, engagement, and consent requirements between mining companies and local communities. New law should also feature monitoring requirements and a penalty system for companies that fail to educate communities, comply with Indigenous resource protections, or properly manage waste. Specific protections should be instated to ensure that new mines are not proposed at sacred or culturally significant sites.

- Encourage Federal Departments to require due diligence processes like the UN Guiding Principles on Business and Human Rights, the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, and the World Bank Environmental and Social Framework, that each require some measure of FPIC.

Want to receive our Plug Into Policy monthly newsletter?

You can be the first to know when we publish new reports. Sign up in just a few seconds.