The transition to electrified transportation is here, and the Biden-Harris Administration’s Investing in America Agenda is accelerating progress. The agenda includes legislation like the Bipartisan Infrastructure Law (BIL) and the Inflation Reduction Act (IRA). This legislation supports activity across the EV industry, including $7.5 billion for the roll-out of 500,000 electric vehicle (EV) chargers across the country, additional funding to support domestic battery and EV manufacturing, and EV tax credits for consumers. Thanks to the Investing in America Agenda, we have seen over $200 billion in private sector investment in new EV and battery manufacturing and supply chain facilities. These investments have spurred the creation of over 240,000 new EV and battery manufacturing jobs in the U.S.

Research shows that U.S. auto facilities producing electric vehicles are requiring more jobs and a larger workforce than traditional gas vehicle facilities.

What’s more, along with all of the new EV jobs and facilities announced in the U.S. auto supply chain, there are other jobs necessary to support the transition, including jobs to conduct the design, creation, and maintenance of a nationwide charging network. Those jobs for charging network buildout and ongoing maintenance include engineers, software developers, planners, electricians, construction workers, and more.

More jobs are a benefit of a domestic, circular battery supply chain

The buzz around the EV transition and the creation of batteries and vehicles here in the U.S. is undeniable. One currently overlooked part of the supply chain, brimming with opportunity, occurs at an EV battery’s end of life.

To support a domestic supply of minerals used to manufacture batteries, the IRA includes domestic sourcing requirements for vehicles to qualify for the federal EV tax credit for consumers. This domestic sourcing requirement can be satisfied if the minerals are recycled in the U.S. after their initial use. The IRA automatically qualifies EV battery materials recycled in the U.S. as American-made, regardless of their place of origin.

As a result, there has been a push to dramatically expand recycling in the U.S. to take advantage of federal incentives, strengthen our domestic supply chains, and meet mineral demand for the EV transition. Today’s EV battery supply chain is geographically concentrated in just a few locations far apart from each other. If any disruption is experienced in the few places where battery mining, refining, processing, or assembly happens, the entire supply chain is impacted.

To produce a battery, the minerals that make it up must travel an average of 50,000 miles, which leaves the supply chain vulnerable and spread out. A domestic, circular battery economy, where EV batteries are repaired and reused, repurposed, or recycled at their end-of-life, can help the global supply chain withstand these disruptions by reducing our need for mining and keeping the materials that we have mined in use. Ensuring this activity happens right here at home means more jobs in the U.S.

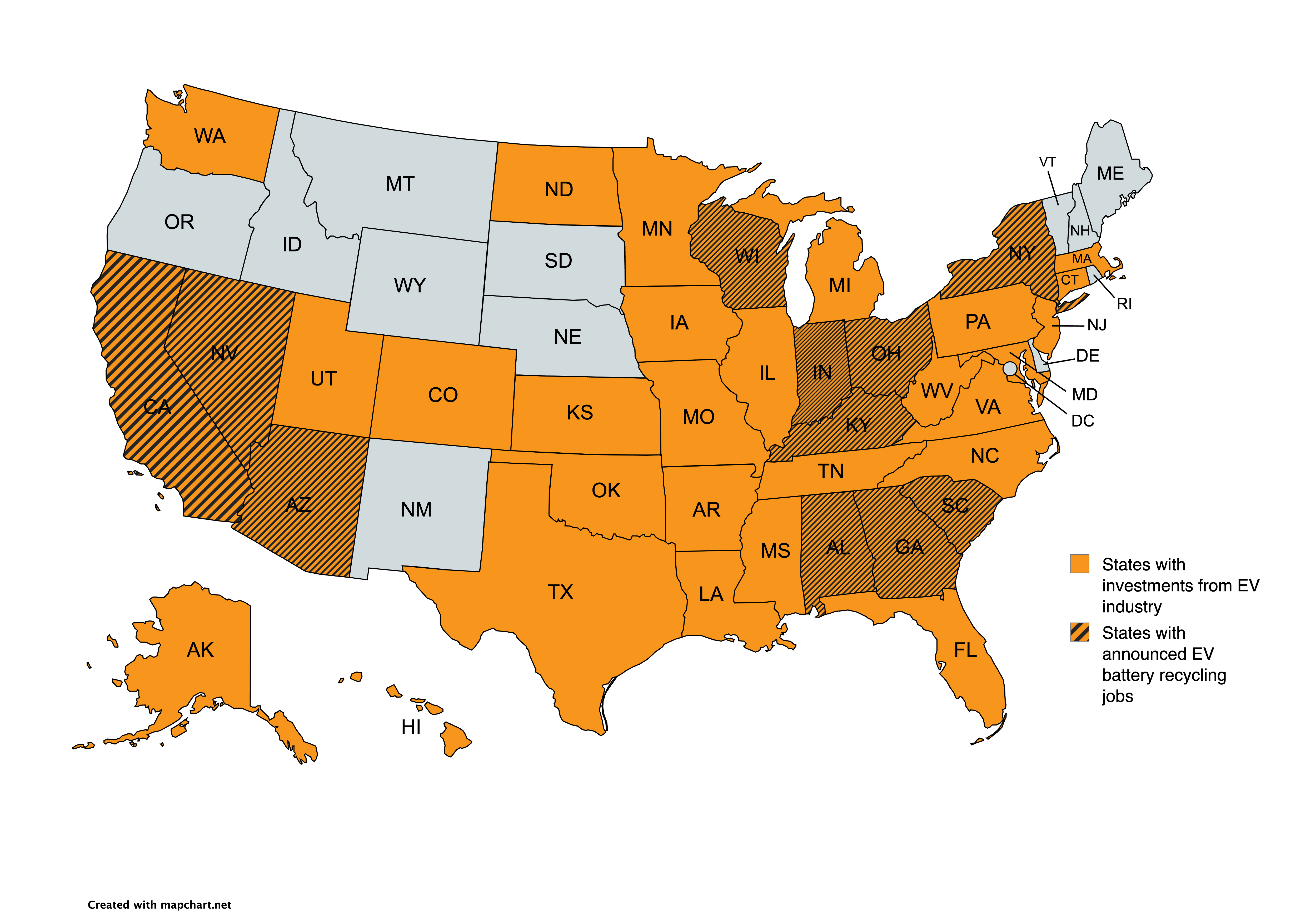

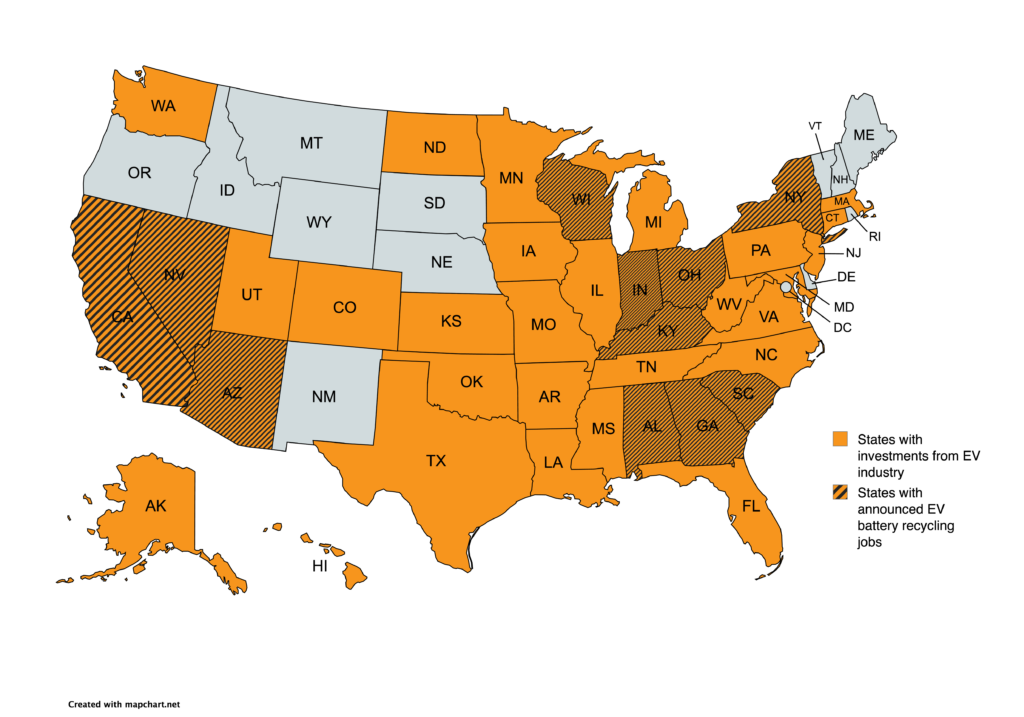

From 2022 to 2024, $7.8 billion in investments flooded into battery recycling, creating thousands of new jobs, including more than 1,500 in Nevada, 1,800 in South Carolina, and almost 300 in Georgia.

A circular economy will need the support of industry and workers. Promoting a circular battery economy includes extending the useful lifetime of electric vehicles through battery repair, recycling, reuse, and repurposing. After their lifetime powering a vehicle, EV batteries typically retain around 80 percent of their original capacity, making them an excellent fit for second-life applications where they can be remanufactured and reused directly in another EV application, such as in a vehicle requiring shorter travel distances. Another option is to repurpose batteries for off-road stationary energy storage applications. We will need infrastructure and people to mobilize these circular economy solutions.

Racing forward to more jobs

EV investment and job growth are currently happening across the U.S. and are concentrated in states like Georgia, Michigan, Tennessee, Indiana, Kentucky, Nevada, Ohio, Alabama, Arizona, Kansas, and Texas. Moving forward, EV and battery manufacturing could generate up to 931,000 additional jobs in the broader economy.

Already, several facilities have popped up across the country to support domestic manufacturing and a circular battery economy:

- Georgia boasts production of EVs from legacy manufacturers like Hyundai and will be home to EV-specific manufacturers like Rivian.

- In Oklahoma, ATC Drivetrain works to expand battery remanufacturing to support the industry’s global migration to electrification. ATC Drivetrain is also engaged in battery reuse and recycling.

- IT eCycling Solutions is an end-of-life battery processor located in Tennessee. It assesses used batteries and recycles them for raw materials or repurposes them.

- Michigan-based auto manufacturers, including GM and Ford, are ramping up EV production in the state and across many of their other facilities.

- Li-Cycle is a lithium-ion battery resource recovery company with facilities in Arizona and New York.

- GlobalTech Environmental is located in Wisconsin, and along with recycling, the company offers remanufacturing for battery reuse.

- In North Carolina, Cirba Solutions works to collect batteries at their end-of-lives to prevent them from ending up in landfills and to tee them up circular economy pathways.

U.S. EV and battery manufacturing continues to race forward, driven by groundbreaking federal policies that have accelerated economic investment and job creation. Circular economy solutions like repair, reuse, repurposing, and recycling should increase as the EV industry grows to keep valuable materials in use in the U.S. By ramping up investment in a circular economy across the country, we can ensure a domestic supply of minerals necessary for EV batteries, which decreases both our dependence on other countries for minerals and the need for mining. A circular economy can create even more jobs here in the United States.